THE FOREST INDUSTRY OF THE FUTURE: What Will It Look Like?

-----------------

I was recently asked to speak at the North Carolina Forestry Association’s annual meeting in Myrtle Beach on the above captioned topic. Before agreeing to the talk, I had to think about it for a while. The quote “Its tough to make predictions, especially about the future” attributed to Yogi Berra, as most quotes are, hung in my mind for a few days. But I took a shot at it and later agreed to share some of those thoughts with TMS readers.

First, there has to be a basis for the prediction. The basis that I chose was to look at the changes occurring in the forest industry and to look at what I thought the future economic environment might look like.

The three key changes in progress are:

1. Changing Timberland Ownership

2. Biomass for Energy

3. Global Industrial Revolution

Timberland Ownership: The shift in ownership (from forest industry to institutional) is well documented and well underway so there is no need to spend time on it (maybe a couple of comments!). Due to the housing/lumber market collapse, timberland owned by the sawmill industry is following in the footsteps of that formerly owned by the pulp and paper industry. This is illustrated by the timberland ownership shifts of Allegheny Wood Products and Anthony Forest Products to TIMOs. Survival can be tough. The second point is that the institutional owners have no allegiance to a mill so the wood will flow to the highest bidder.

Biomass for Energy: This is not a new thing but its impact is changing and the magnitude of the issue is not universally well understood so it merits significant discussion. There are three drivers pushing the biomass market shift.

- Renewable Energy: The desire to shift to energy sources that we cannot “run out” of. Many states already have legislated renewable energy targets and biomass, particularly in the Southern states, is playing a key role toward the advancement of those goals.

- Climate Change: The desire to shift away from energy sources that add to the perceived problem of man caused global warming. Burning wood is carbon neutral when viewed from a carbon cycle perspective. This appears to be more of a political issue than a scientific one but that is irrelevant to the outcome. Pellet exports from the U.S. to Europe increased over ten fold last year fueled by carbon taxes in EU countries. If Cap and Trade is passed here, expect to see an even greater shift from coal to biomass by utilities.

- Energy self-sufficiency: This is the most important concern from my perspective. It is significant from both national defense and economic security points-of-view.

So where will this biomass come from? The primary sources of woody biomass are manufacturing residues, harvest residues, urban waste (construction, etc.), pulpwood and short rotation crops grown specifically for biomass. I have looked at available manufacturing residues for multiple clients and there is just not a significant amount available. It is virtually ALL being used and most of it is used by the forest industry to produce products or energy. Harvest residues are there BUT, as the pulp and paper industry knows, harvesting residues is expensive, they have a negative impact on mill processing and they produce a product of inferior quality and value. These traits are equally true for pellets and pulp. I don’t know much about urban waste but there is less of it with the housing market decline. So that leaves pulpwood and that is where the bulk of the woody biomass resource will come from.

To better understand the magnitude of potential biomass demand, let’s look at some of the new facilities.

A Pellet Mill: The pellet mill in Cottondale, Florida started up in April 2008 as the largest pellet production facility in the world. One hundred percent of the plant’s production is for export to Europe where the pellets are mixed with coal to reduce carbon emissions in the production of electricity. The driver behind it is the European carbon tax applicable to coal but not the carbon neutral wood pellet. The plant produces 560,000 tons of pellets annually and consumes about 1,000,000 green tons of wood. The resource used is not “residue” - it is pulpwood. This facility is the equivalent of a new pulp mill.

Cogeneration: This is certainly not new in the forest industry as our pulp mills have been doing this for a long time. What is new is the magnitude of the projects. Industry is expanding the use of cogeneration, schools are installing the systems and one village in Pennsylvania is building a system to use the steam to heat all of the houses in the village as well as supplying the electricity to them. An industrial example is the Sonoco / Peregrine Energy Corporation plan to develop a new $135 million woody biomass-fueled cogeneration plant in South Carolina. Plans are for Peregrine to construct a new 50-megawatt capacity facility that will be capable of generating enough electricity to power approximately 14,000 homes. The new biomass-fueled cogeneration facility will replace Sonoco's existing coal-fired boilers. Peregrine intends to sell the entire electrical output and all renewable energy certificates associated with the plant to Progress Energy Carolinas, Inc., and low pressure steam from the plant to Sonoco for use in the manufacture of recycled paperboard and other converted products. “The project would benefit the regions' forestry industry by utilizing pre-commercial thinnings and waste logging residues as the woody biomass fuel for the project.”

As a rule of thumb, a 100-megawatt plant will consume about a million green tons so this facility will consume about one-half of that but that is still a lot of precommercial thinnings!

A Coal Fired Power Plant: This one really caught my attention. The power companies are struggling with the renewable energy standards. In the East, there is limited opportunity for wind, solar or geothermal so biomass is about the only alternative left (hydro is out for a multitude of reasons). FirstEnergy at Shadyside, Ohio has announced its conversion from coal to biomass. The largest proposed development to date had been Yellow Pine Energy's 110 MW project in GA, a million-plus ton/year wood consumer. FirstEnergy’s is 312 MW and will consume 3 million green tons! This is on a par with the South’s largest pulp and paper mills.

The sheer quantity and magnitude of the announced facilities similar to the examples above is staggering from a resource consumption viewpoint. Not all of them will come to pass but it is very clear that enough of them will reach production levels that will greatly impact the future supply/demand picture for forest products.

Global Industrial Revolution

: The third key change, the global industrial revolution, is well under way but it may never be realized. All of the developing nations have ambitions to reach the standard of living with which we are blessed but the commodities, the natural resources, are just not there to reach that level on a global basis. Commodity shortages, particularly oil and other transportation energy sources, will prevent the world from reaching the level that we have obtained and, more than likely, those same shortages will prevent us from maintaining that level. Escalating transportation costs will cause us to revert back to a society much more dependent on manufacturing. It is significantly less expensive to ship dried lumber than logs.

The three key changes mentioned above combine with a couple of additional economic factors to create the drivers that define my view of our economic future. The drivers are:

- Social drive for renewable energy, energy self-sufficiency and climate change

- High energy costs- The key cost escalator

- High Inflation Rate (perhaps hyperinflation) driven by:

* Very high government spending

* Very high oil prices

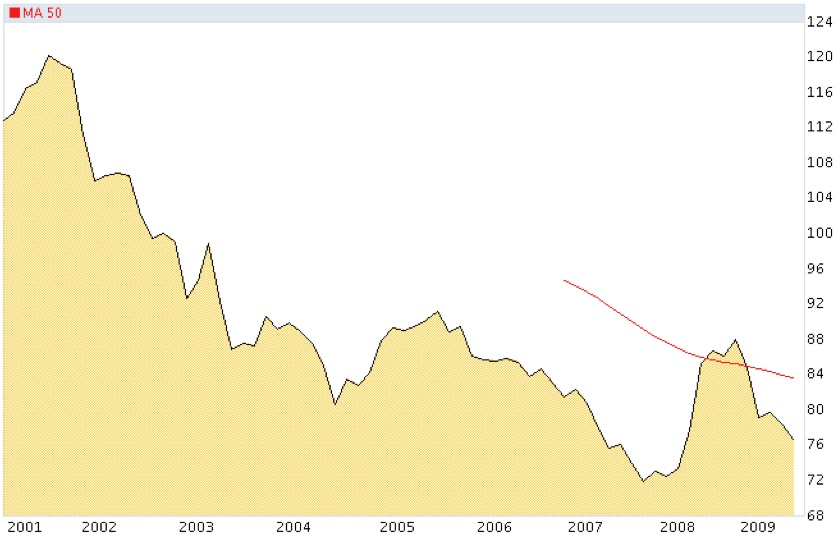

* Commodity shortages, including timber - Declining Value of Dollar (see Figure 1)

The Future of the Pulp Mill

: Domestic paper demand will continue its downward trend but I am not as pessimistic about the industry’s future as most people are. The continuing decline in the dollar, although very bad for the consumer, will have a positive impact on the pulp and paper industry. The export market will be much brighter. A great deal of capacity has already been taken out of the market. Although bio-refinery economics are very unclear at this time, more capacity may come out as some mills are converted from pulp to production of “of ultra-clean, renewable motor fuels”. As the energy transportation costs rise, it may be cheaper to burn pulpwood for energy and to convert black liquor to transportation fuels. The key driver is the future price of oil and that may be considerably higher than the current consensus. The major downside for the pulp and paper industry will be the competitive demand for wood. Wood is both its raw material and its energy source and the power companies are going to be very tough competitors.

The Future of Sawmills

: Despite the doom and gloom about future housing, domestic lumber demand driven by housing demographics still looks good after the excesses have been worked off. The Global Industrial Revolution combined with a weaker dollar will create a very positive manufacturing and exporting environment for sawmills. Global housing and lumber demand will be high and the U.S. will be one of the key suppliers. Very high energy costs make it more cost effective to ship lumber than logs to export markets, reversing the current norm. There will be a much more competitive market (higher prices) for mill residues. Consistent and steady demand from biomass consumers will provide a steady supply of logs from producers. Things couldn’t look much better assuming there is a mill somewhere that survives the current crisis! It’s always darkest before the dawn.

The Future of Biomass Consumption

: Biomass utilization is a game changer in the forest industry because of the sheer quantity of biomass that will be utilized. Many schools in cold climates are heating with wood chip boilers today and they are saving money without any subsidies (and this is spreading to the warmer South as well). European villages have moved in that direction and some Canadian and U. S. villages are capitalizing on their experiences. The developing demand by the power companies seems so huge as to be unsustainable. Transportation cost increases will work against the large biomass programs such as the 3 million G ton Ohio facility. Power facilities with less output and shorter haul distances will be more cost effective (diseconomies of scale). If the “man-caused” global warming issue does not result in tax legislation, if consumers scream too loudly about electrical cost increases, government may back off and the power companies will be able to revert to coal to produce electricity more economically. That would take the pressure off biomass and still provide energy self-sufficiency to a degree. But even that scenario will not change the shift to biomass for energy. Oil is a finite resource and more energy must be expended to get each additional barrel. Like it or not, oil prices are on the wrong end of the power curve and that means that transportation costs are too. There WILL come a point, I don’t know when, where cellulosic ethanol (or one of the other wood-based transportation fuels) is less expensive than oil. When that happens, the forest industry is changed forever.

The Future in the Forest:

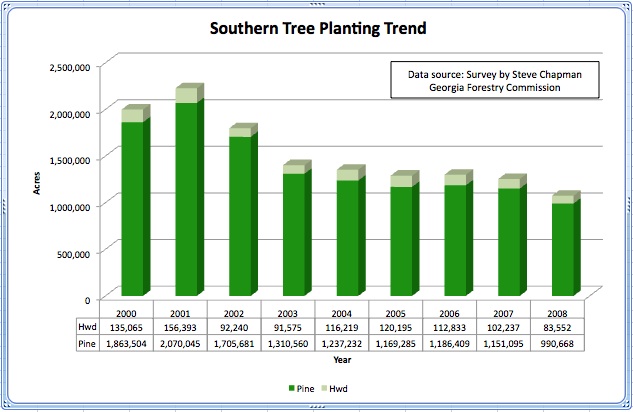

Recent economic drivers supporting longer rotations are creating a “wall of wood” in the sawlog size class. Institutional investors have lengthened rotations from the pulpwood size-class to the sawtimber size-class to capitalize on the price differential. Sawtimber sales have been deferred as a result of poor markets, so harvest followed by planting has slowed (Figure 2).

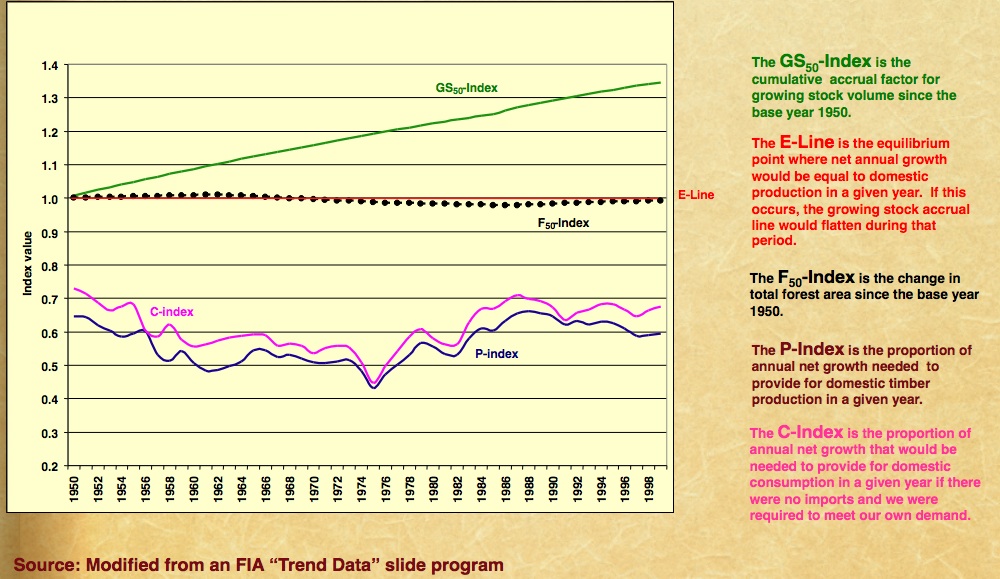

The graph shows a significant decline in planting, which is troubling to some folks, but more likely reflects increased thinnings and significant reductions in clearcutting. Short rotation energy plantations close to market will happen IF wood costs go up significantly OR planners fail to anticipate increases in transportation costs. There will be more “in-woods” operations (chippers, biomass harvesting, biochar, and perhaps mobile methanol) – all driven by higher oil costs. Biomass harvests will be incorporated into conventional tree planting prescriptions. Much more competitive markets will mean higher stumpage prices for biomass and pulpwood. The current growth/drain ratios are very favorable (Figure 3) but sustainability will probably become a political issue if not a real one.

Changes in Wood Supply Chain: It is the same basic Wood Supply Chain, but…

- Harvest residues will be added, probably more mechanized

- Biomass demand brings more stable wood demand

- No monthly (weekly, daily) shifts in mill consumption

- No shifts in species needed

- Annual contracts for wood producers become practical for biomass production – good news for loggers!

- May force the same for pulpwood and sawlog buyers

- Logging will become a more robust, stable and competitive market segment

My Synopsis of the Future Forest Industry

- Biomass/Power companies will be a key part of the industry.

- There will be more “in-woods” operations (chippers, biomass harvesting, biochar, and perhaps mobile methanol).

- A smaller pulp and paper industry will survive and exporting will play a larger role.

- Sawmills: Demographics still favor housing and lumber export market will become significant. Imports less competitive.

- Logging contractors will have a more stable operating environment. Annual production contracts.

- Stumpage market will be more competitive and more stable.

- Plantation establishment will consider energy market.

- Timberland ownership will be a good place to be!

So that’s the way I see it. A global economy responding to a failed energy policy built on unsustainable oil production. This view of the future may not be right but it is worth considering as you go forward.

---------------